From a blank slate through to daily PDCA cycles, leaders have significant influence over the efficacy of continuous improvement frameworks. In this article we discuss how to amplify this influence and share the responsibility with all stakeholders for sustained success.

Building an effective continuous improvement framework is crucial for any organisation striving to achieve long-term success. As an improvement leader, you play a critical role in building this framework and ensuring it is simple, adaptable, and scalable.

Taking advantage of the opportunities that digital provides makes building a robust framework that provides visibility, insights, and stimulates intentional communication / action, easy for all involved.

Remember to keep it simple

Simplicity is key when it comes to effective, continuous improvement frameworks. It must be easy to understand, implement, and evolve. Your framework must ensure that it can adapt to changing circumstances and scale up to meet growth and expansion.

Think about the scalability of any system or process you put in place. Can it be replicated and/or implemented without compromising resources and improvement capability? Is the framework inclusive of everybody’s technical knowhow – or at least built to instil that knowhow easily?

This case study highlights the impact and application of our improvement system org-wide.

Like many improvements, a good measure of effective continuous improvement frameworks is how quickly a stakeholder who has not been involved in their conception can understand and work within them.

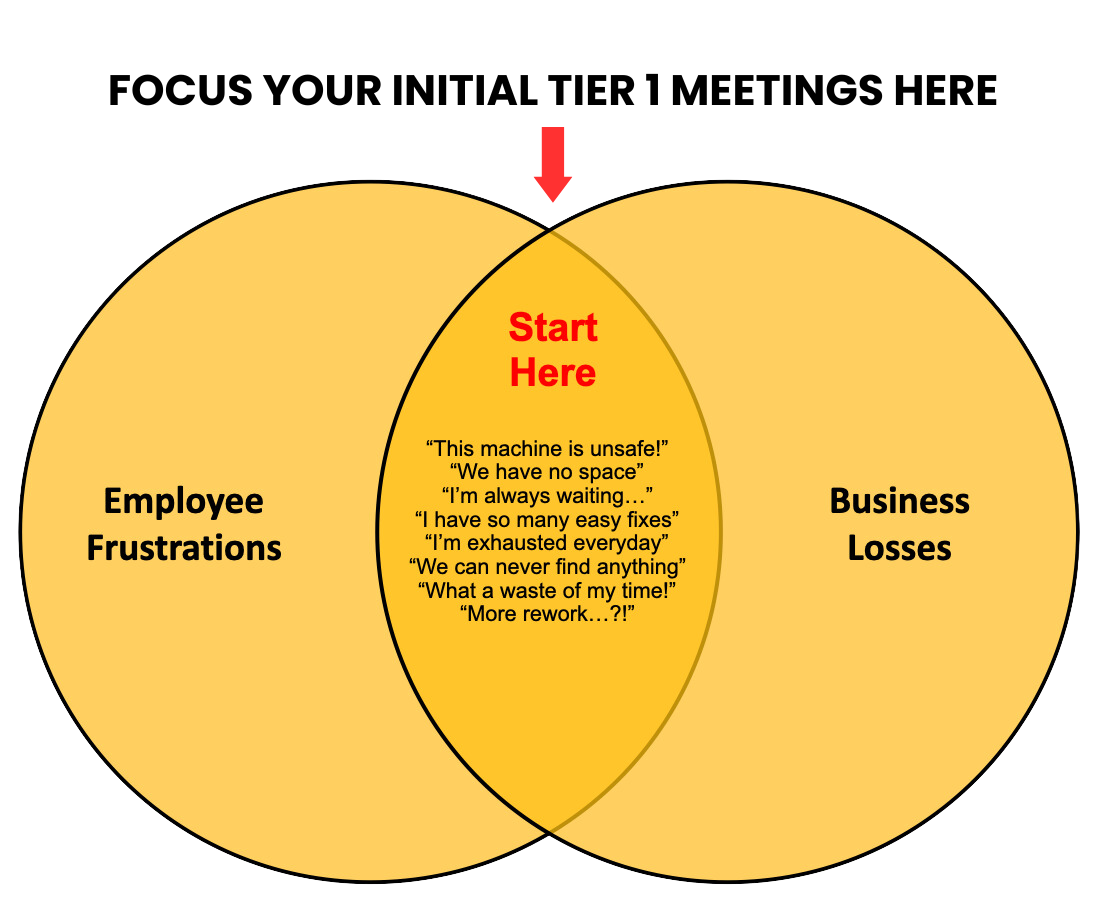

Tiered meetings are the first step towards operational excellence – so if you’re not yet running these (or running them effectively) at the frontline, you should be. This initial step will allow your people to work on the CI framework whilst including them in its development. It really is as simple as asking the basic questions daily:

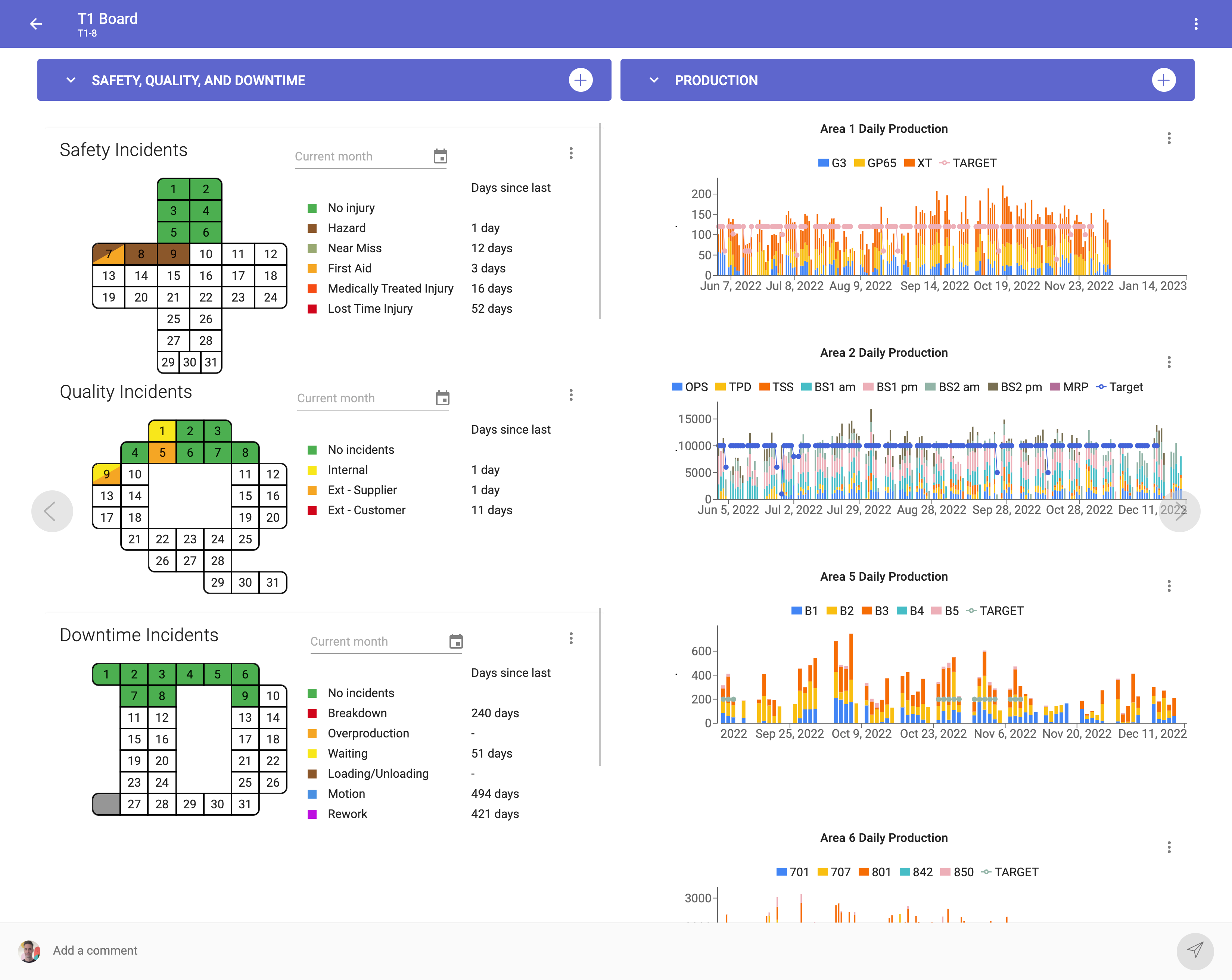

The most effective continuous improvement frameworks are supported by digital systems

Taking your improvement systems digital can not only unlock new possibilities, it also takes advantage of your average employees reflexive understanding of mainstream ‘household’ technology. A digital framework provides scalability without the need for additional resources or significant investment once setup.

It can provide visibility of improvement, as well as insights at all levels and functions of the organisation. It creates a form to follow and practice that can easily evolve to meet current best practices and the needs of all stakeholders.

You can get laser-focused, meaningful improvement projects, supported by real-time data capture and activity-specific feedback. That leads to quick decisions and follow up activity.

Unlike improvement activity under a static, manual framework, insights are gained instantly at all levels as the data comes in. Our people can then easily drill down into data they need and uncover trends, patterns, and insights that can help drive further continuous improvement efforts.

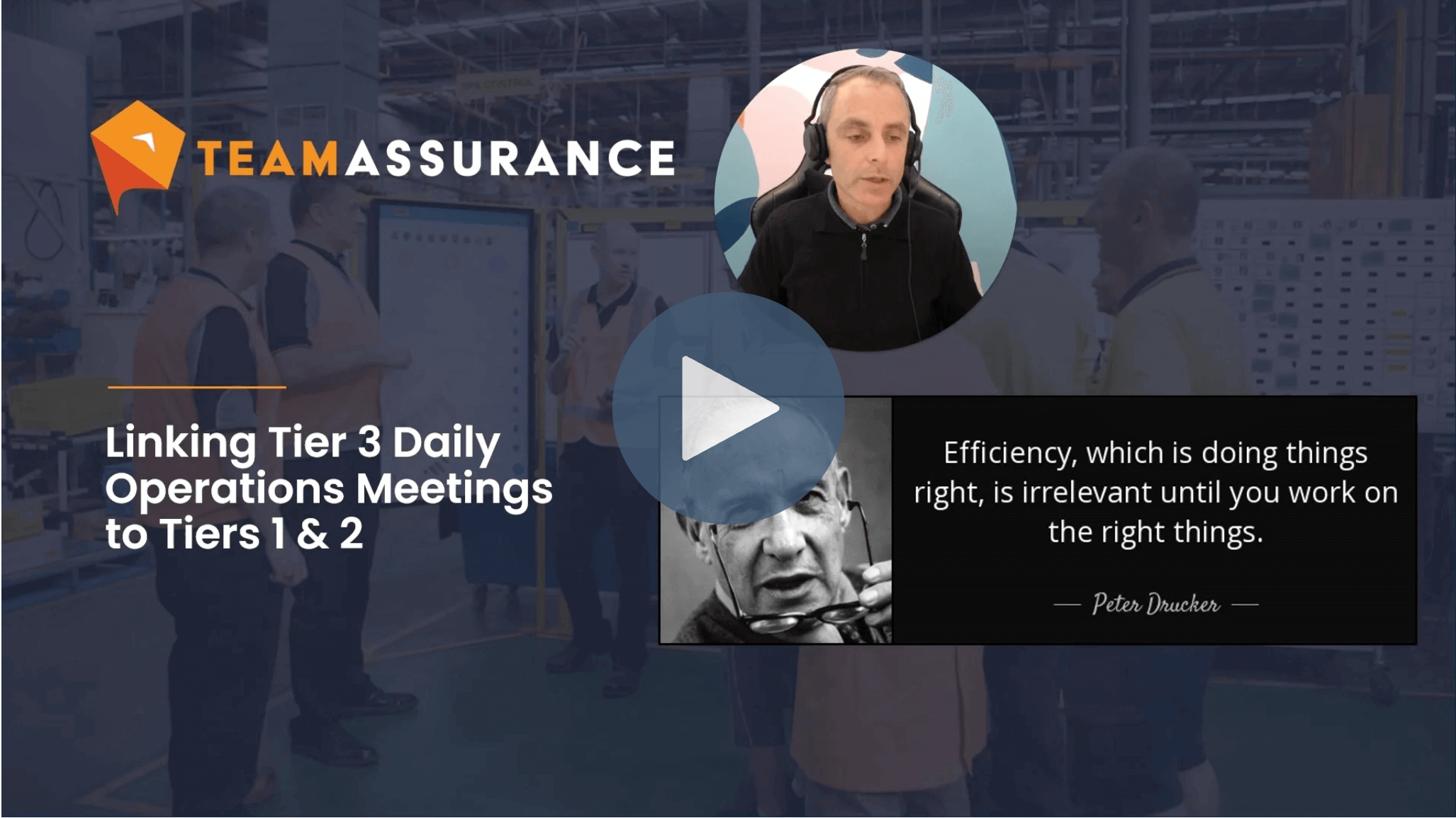

The video below highlights how much more meaningful and contextualised information can be when presented using a digital daily management system:

Data is captured in the course of work; available when, where, and how it is needed for our specific teams. No running from board to board, logging into multiple systems or flipping through multiple clipboard charts.

Our people have a centralised platform that allows everyone to work ON the business whilst working IN the business. Not to mention the ability to optimise any part of the improvement framework without turning adjacent processes obsolete.

A Connected Continuous Improvement Framework, Not Just Locally Optimised ‘Islands’

For any improvement activity flow to not only be sustained, but to thrive, it must be supported by adjacent processes and systems. So when implementing tools and allocating resources we must consider how the various elements interconnect. We don’t want to optimise or develop them in isolation.

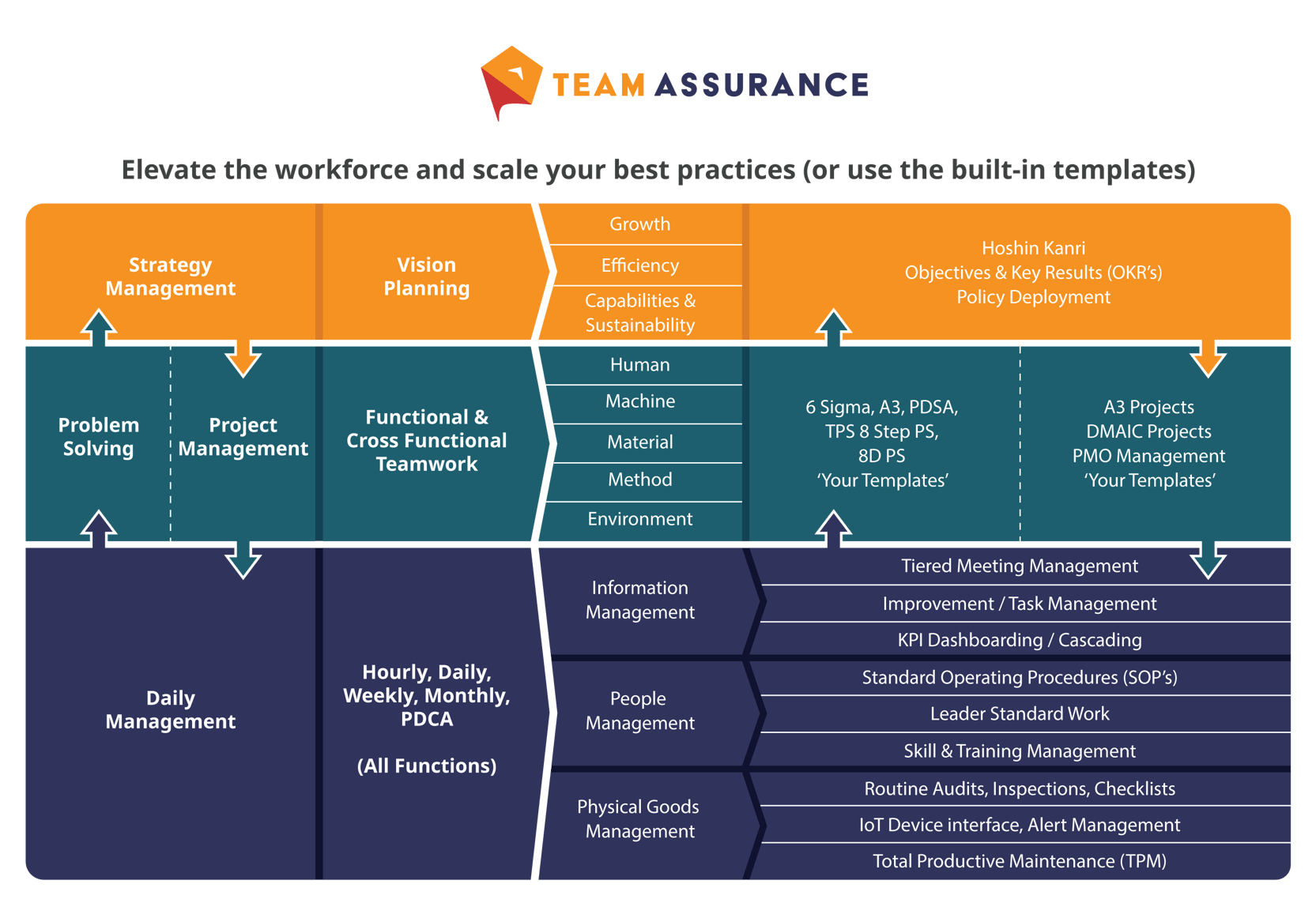

Tools like Leader Standard Work, standardised problem solving techniques, and a Tiered Daily Management system should work together to handle the full PDCA loop.

The picture below how we designed TeamAssurance to avoid disconnected ‘Point Solutions’ (digital or analog) that do not help, or even act as roadblocks, to achieving an effective framework for continuous improvement.

Want to explore how improvement activity can be supported by digital-aids to Lean tools? If you’re a Business in need, or a Consultant with clients in need, contact us for a demonstration of the TeamAssurance platform today.