Are You a Learning Organisation?

Paul Dunlop examines what it means to be a learning organisation and outlines the common elements among environments that facilitate high-performing teams.

Does Your Improvement Activity Flow Like a Dripping Tap or Torrent?

In this article we outline the essential ingredients for consistent, effective, daily improvement activity within an organisation.

Hoshin Kanri: Linking the Top to the Bottom

Paul Dunlop explains how Hoshin Kanri, supported by adjacent Lean processes, facilitates effective strategy planning, deployment and execution.

Creating and Identifying Lean Superheroes

Turning our people into Lean Superheroes (and identifying them) requires asking a few questions and an investment of time / resources writes Paul Dunlop.

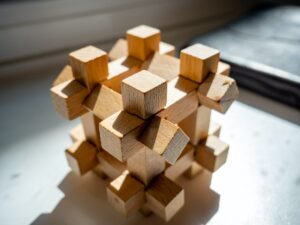

How do the Lean tools and principles connect?

The array of lean tools and concepts can be quite overwhelming. We explain how these continuous improvement elements connect and fit together.

Lean Innovation: Hybrid Digital Kamishibai Boards

These hybrid digital kamishibai boards are a great example of how organisations can blend traditional Lean tools with digital solutions for great synergy.

Continuous Improvement Planning: A Key Step

It is a simple, but often overlooked, critical step in the improvement process. Read why we must focus on continuous improvement planning for success.

Keeping Lean Simple

All too often when challenged to make improvement in our process environment we look for the complicated ‘shiny objects’. We discuss keeping lean simple.

3 Tips to Optimise Your Daily Huddles

Optimise your daily huddles by considering these key tips and make the most of your improvement activities.