Lean Thinking is All About Discipline

Lean thinking requires discipline and an adherence to principles and processes. We discuss the structures needed to achieve significant change via Lean.

Creating and Identifying Lean Superheroes

Turning our people into Lean Superheroes (and identifying them) requires asking a few questions and an investment of time / resources writes Paul Dunlop.

Hoshin Kanri: Linking the Top to the Bottom

Paul Dunlop explains how Hoshin Kanri, supported by adjacent Lean processes, facilitates effective strategy planning, deployment and execution.

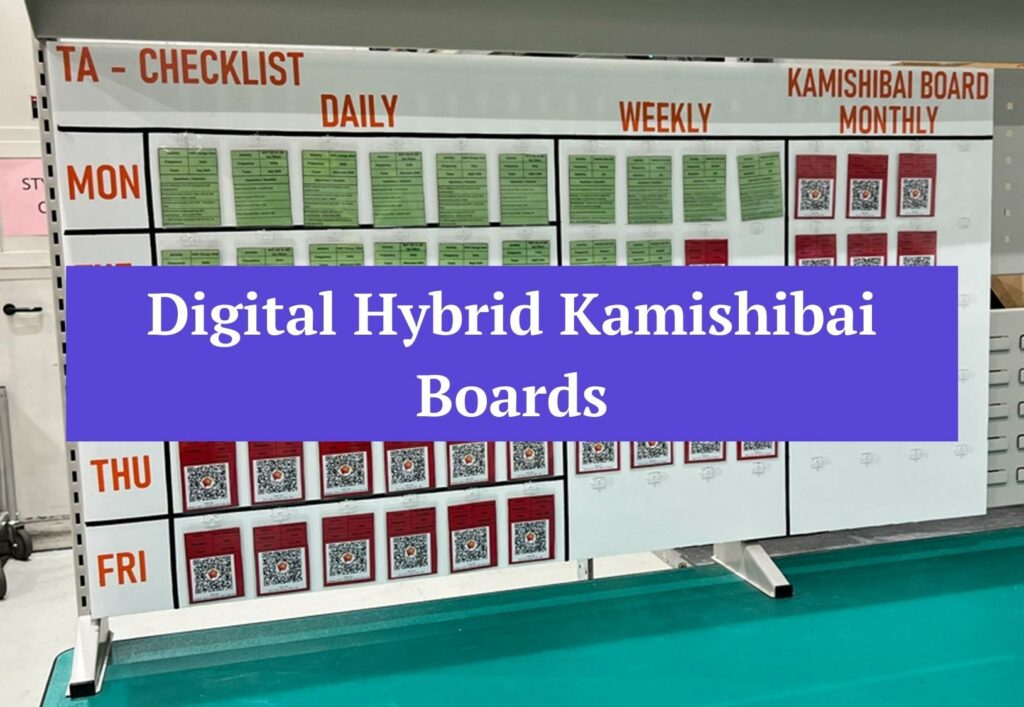

Lean Innovation: Hybrid Digital Kamishibai Boards

These hybrid digital kamishibai boards are a great example of how organisations can blend traditional Lean tools with digital solutions for great synergy.

Standards – The Bedrock of Improvement and Operational Excellence

Implementing standards doesn’t mean eliminating ownership of tasks from staff. We discuss how a foundation of standards strengthens improvement efforts.

Rewarding Employees and Understanding Motivation

Rewarding employees effectively isn’t a science, nor is it straightforward. But, by better understanding motivation we can better reward our teams.

The Control Chart: Mapping Process Behaviour

The control chart (or process behaviour chart) is one of several visual tools typically applied to quality control analysis. We discuss how to use it.

Unlocking Employee Potential

Maximising employee potential is at the core of Lean yet often overlooked. We discuss how to get the most from this crucial resource.

Scaling and Sustaining an Excellence program

NCI Packaging was buckling under the volume of improvement projects until they adopted an online platform for sustaining an Excellence program at scale.

Lean and Operational Excellence books

The best Lean and Operational Excellence books explore culture, teams and systems thinking. Here’s the 3 books that have excited us the most so far in 2019.